- Home

- Products

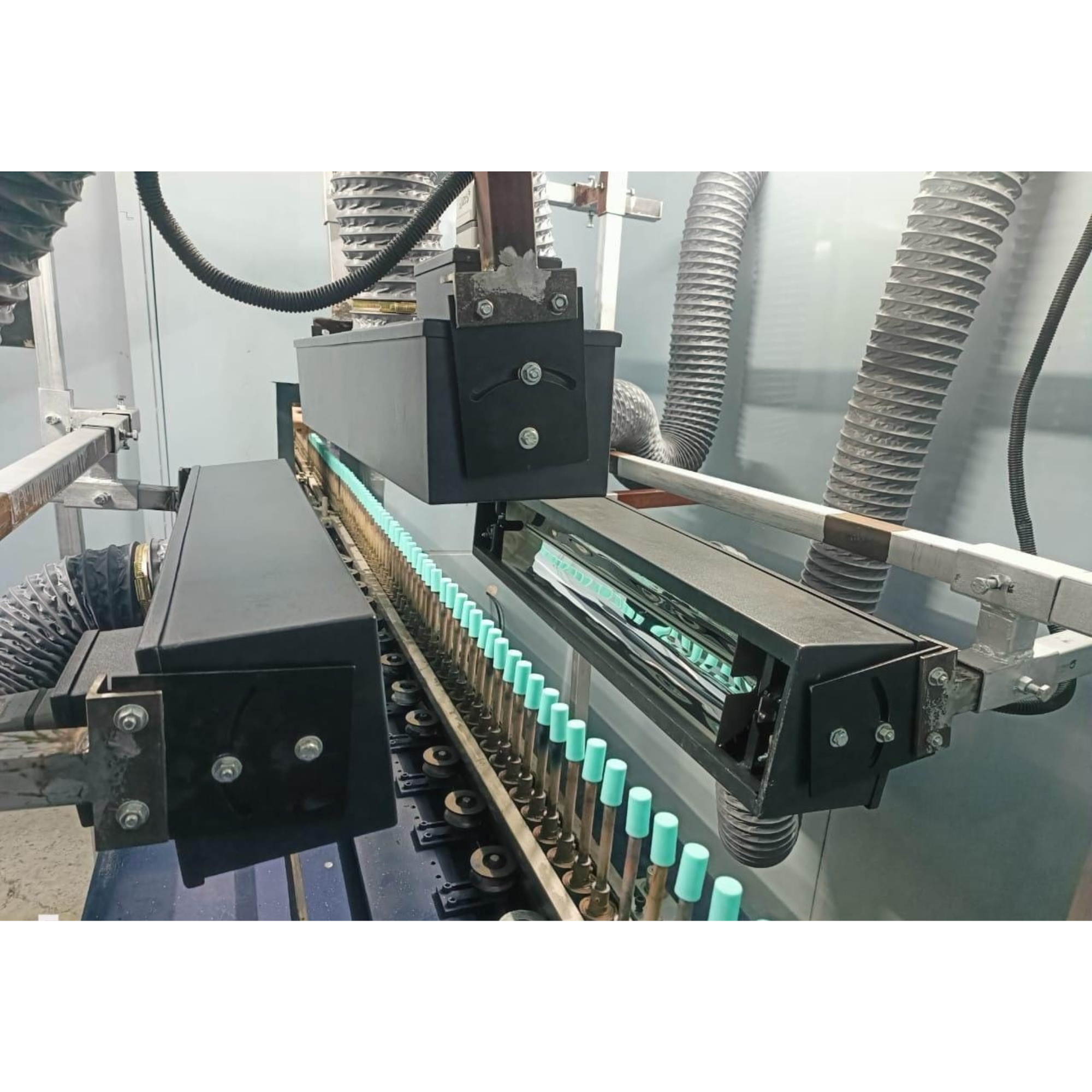

- Conveyorized UV & IR curing system

- Shuttered UV Curing System (Air Cooled or Air + Water Cooled)

- Non – Shuttered UV curing system

- Roller Full Coating System

- Anilox Coating Attachment System

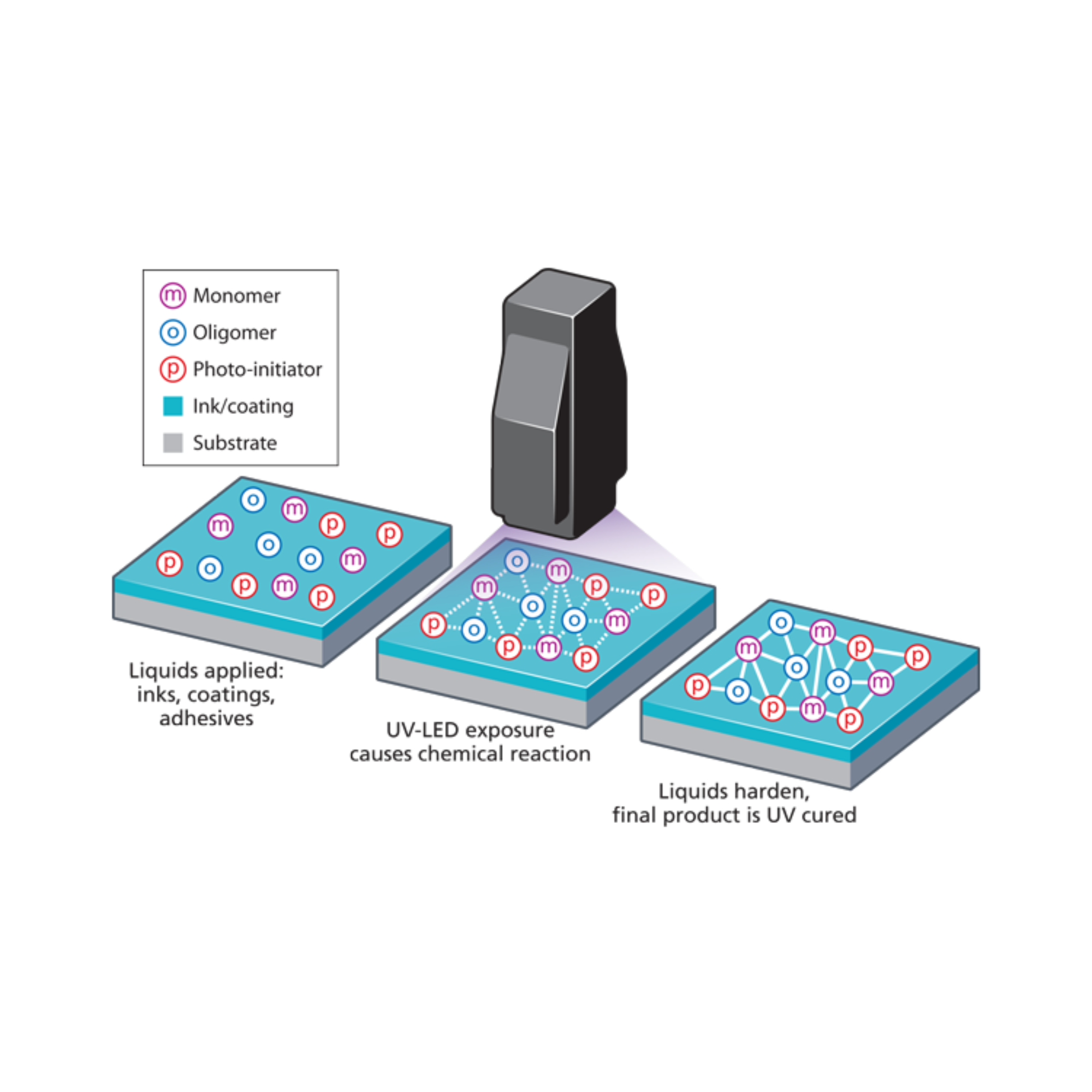

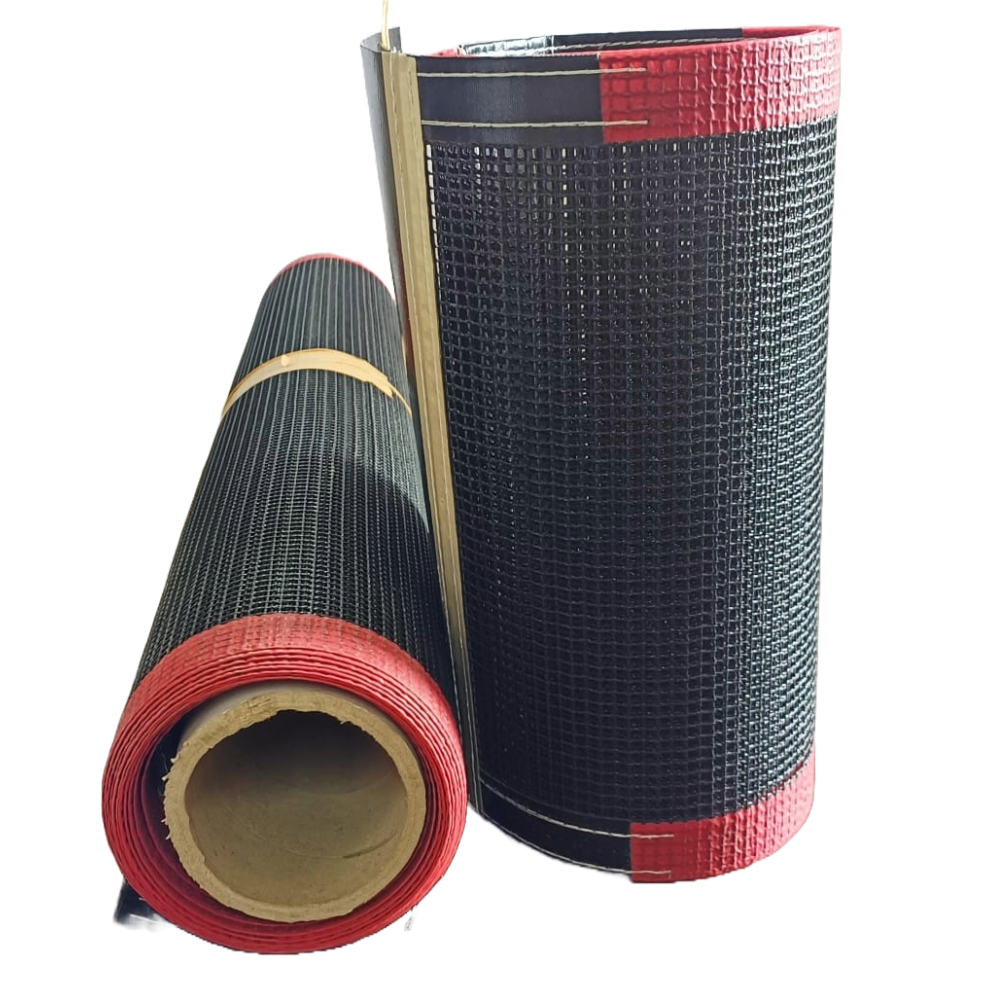

- LED UV Curing System

- UV Lamps, IR Lamps and Heaters

- UV Power & Control Components

- Other Products Specially Designed for UV & IR Curing System

- About Us

- Contact Us

- Home

- Products

- Conveyorized UV & IR curing system

- Shuttered UV Curing System (Air Cooled or Air + Water Cooled)

- Non – Shuttered UV curing system

- Roller Full Coating System

- Anilox Coating Attachment System

- LED UV Curing System

- UV Lamps, IR Lamps and Heaters

- UV Power & Control Components

- Other Products Specially Designed for UV & IR Curing System

- About Us

- Contact Us